Back in the 19th century, people were using the pantographs manual engraving machines to make anything of their choice. Engraving would therefore take several hours, days or even weeks before you get an individual item done. Back then, it was a matter of how fast you could be or how versatile you can be. However, a few years down the line, there was the big introduction of the computerized rotary engraving machines. These new models, ensure that the print work is not only simple but convenient too. Instead of tracing the item to engrave like it was with the manual machine, now people started to type and send messages to the device, and the item is engraved within minutes.

However, before people would rest and continue to enjoy the services of this machine, technology advanced again and there came another machine, the Laser, which further simplified the job. Once again, this device reduced time and labor for engraving significantly. While rotary engraving machine were using engraving cutters to mark materials, the laser uses a beam of light to achieve the same results. Both machines have significantly changed the engraving world. Although there are people who still use the old pantographic methods occasionally, there are those that prefer laser over rotary and reverse. Others love using both machines for specified reasons. However, both machines have their advantages in the marking market. They can both produce customized and personalized products that have the ability to engrave a broad range of materials, and finally, they both are suited for different applications.

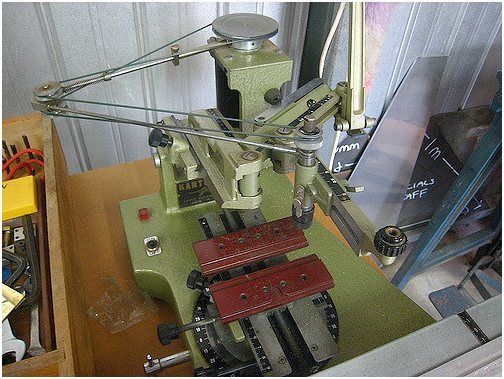

Rotary engraving machine

Rotary engraving machines have applications that are unique and specified for certain use. Although the device has been facing a bigger challenge due to its unfriendly usability, it has one feature that makes it versatile in the industry. It has an electronic surface detection system. This system allows the machine to automatically detect the material surface. Once detected, the Z-axis adjusts to the material to ensure even engraving depths. Therefore making it cost effective and a better piece of equipment especially when you are engraving uneven materials.

Another important feature of the rotary machine is the fact that its fast. This is one of the best things introduced in the market. The current machine has new technological improvements that make it ten times more productive than the first one. The machine has also bypassed the mechanical measuring and replaced it with advanced software like wizards and auto layout visual features making engraving comfortable, faster, and with smoother motion controls. The updates in software are another important thing to note on the machine.

Rotary engraving application

This machine has a large advantage when it comes to print metal materials. It does not matter the type of metal you want to engrave, this machine is always ready to handle all machinable metals including brass, aluminum, stainless steel, gold, platinum, titanium, silver, and pewter. Whether the metal is precious or semiprecious, coated or uncoated, the machine can engrave using the rotating cutter if it’s machinable, while the un-machinable metal is engraved using the non-rotating diamond graver. This application has therefore been the key benefit of the machine.

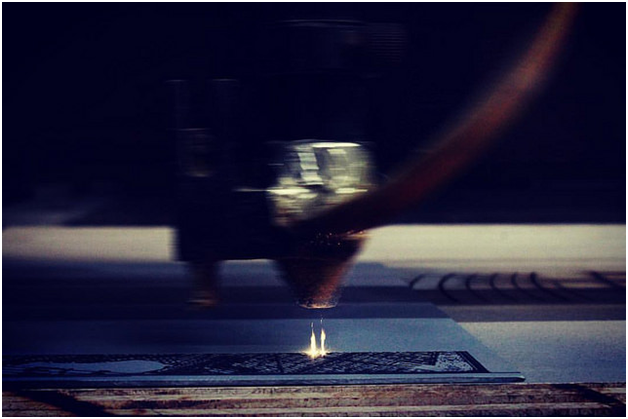

Laser engraving machine

Today, laser machines are more advanced than they were a few years ago. They are faster, cheaper and more user-friendly than their rotary counterparts. Today, the software that was only accessible on the large size machine is now more available in middle-sized machines and at an affordable price. This model of machine has therefore been able to effectively reduce the total time used to the engraving by a significant margin. Unlike the rotary, the laser is more user-friendly therefore making them the most popular machine present on the market. Technology has also been the primary focus of the equipments to ensure that it provides its users with a more versatile machine that can deliver great results.

Laser engraving is a versatile machine with applications that gives you the freedom to engrave. This machine is only limited to your imagination. Whatever it is that you wish to engrave, laser is the tool for you. It works better on the unique applications and materials. This is the area where this machine outshines the rotary by far. Unlike the rotary, with laser, you cannot only engrave coated and acrylic materials faster, but you can also engrave a design on the pockets of your blue jeansisnt this great. This machine gives you the ability to do absolutely anything to meet your demands. Whatever you want to engrave, you will do it like a pro using a laser-engraving machine.

Laser vs. rotary

Both laser and rotary engraving machines are similar, and they can both engrave a variety of materials. All of the machines, as long as you place them on the right use, will give you stunning and personalized results. However, as the machines are similar, they are operated differently, and they both have a different mechanical combination. Although the products from these machines can both be stunning and great, they have a significant difference. Therefore, it will be easy to tell just by looking at the product, which machine was used to engrave.

However, if you are getting to know about the machine for the first time and you have never in your life seen a laser machine while in use or even the product it has ever engraved, then you should try and find the results first before you run for the other. The same also applies to the rotary machine. If you are in the commercial marking business, then depending on what you will be engraving the most, either machine can be to your advantage.

This is because both machines have their strengths and weakness. Therefore, you are the one to choose and see which fits right to your expectations. Alternatively, you can invest in both machines and take your engraving skills to the next level. You cannot find an accurate answer as to which one is better than the other is. However, depending on the materials, you often engrave and the amount of work you have, having both machines in your workshop can be the best investment for you.

Author Bio:

Alfred Stallion is the writer to this article. He is a regular contributor at many sites and mainly focuses on business and technology related topics.

Laser is most preferable for engraving as it is fast and reliable.

I am planning on having a bracelet made for my wife. It will be in either 14k or 18k yellow gold and will have the name of one of her grandchildren engraved on each link in a script font, such as Monotype Corsiva or Lucida Calligraphy. I would appreciate opinions on which engraving method would be better for this.