I posted here recently about a new mobile 3D scanner that appeared on KickStarter as well as at Engadget’s Expand. Moedls was one of the finalists of the Engadget Insert Coin competition and after meeting at the show I had a chance to trade a few emails with the Founder, John Fehr. John is busy perfecting the software of the scanner to ensure full water tight scan outputs, a primary request from the current backs and a necessity for passing a great scan directly to a 3D printer. Being the good natured guy that he is (I say that from a brief meeting at Engadget and the obvious tongue and cheek nature of his Kickstarter video) John was nice enough to answer a few questions I had for him about his history with scanning and the thoughts behind Moedls. Below is the transcript of our conversation.

|

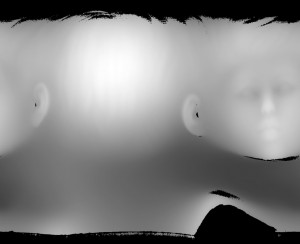

| Flattened 3D Scan from Moedls – Updated to Approach Near Water Tight |

3DEngr: What experience do you have with others scanners? When did you first encounter them and why the desire to create your own?

My only real experience is with the David Laser Scanner. It works pretty well but I found the setup to be a bit tedious, and tended to leave a lot of extra points to clean up. Having to manually rotate it, take new scans, and merge the mesh’s together made it too complex for me to use. You can get nice scans out of it though!

3DEngr: How do you envision people using the Moedls System? Is this for hobbyists looking for some fun or for those in the manufacturing field who will utilize it professionally?

Like the scanner Makerbot showed recently, the best scans will come from cylindrical objects, since the laser works on rotation. I targeted the price more towards the hobbyists, since they have a much more limited budget than the manufacturers.

|

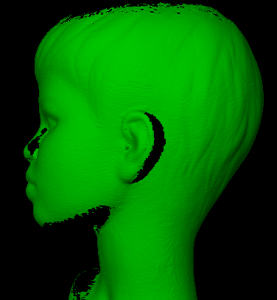

| Moedls Original Output – Some Holes Present |

You mentioned in your Kickstarter feedback that higher resolution and better output came from more capable hardware (cameras and desktop machines), how important is the mobile portion of the scanner as compared to the quality of the scan? Will Moedls work for both mobile and PC and be customizable by end users based on their needs or are you looking to create a closed system?

I definitely want the user to be able to get the best possible scan out of the hardware, and having the software on multiple OS’s with different characteristics (mobility, memory, sensor quality, etc) is very important for that, so that’s what I’m moving towards. I want to keep the ‘mobility’ part as much as possible, but obviously if the software works on a laptop, it’ll work on a desktop as well.

3DEngr: Your prototype at expand looked like it was cut on a CNC laser cutter. How did you create the working prototype?

I bought a number of rotating platforms to test stability/rotation speed before I decided I’d have to build my own to get the characteristics I want. The prototype at expand was based on a platform I bought on amazon for about $135. It’s plastic, and originally had a mirror top, which of course would not work with the lasers, because of reflections. I replaced the top with 3 layers of 1/8″ MDF (to get it as flat as possible) cut in circles, plus a custom bottom that fit into the original fitting for the original mirror top. It was by far the most stable platform I found on the market, but its still not as stable as is needed. The final version (being build now) is made of anodyzed aluminum with extra bearings and a more stable drive system to make the rotation silky smooth.

The MDF was cut out with a Versalser.

3DEngr: What about software, do you design the components and device in 3D before mocking it up, if so which CAD package do you use?

I designed the prototypes with Sketchup, and use the SVG exporter to create an SVG file that the versalaser software can import.

3DEngr: Looks like you have a few different Kickstarter campaigns, how has your experience been in the past and did you always know you would be putting moedls there? It has a much higher funding goal, were the others done before you conceived of the moedls project?

Kickstarter has been great! I haven’t made a ton of money (I think most of them barely broke even in terms of how much I spent and how much income I got) but the feedback and suggestions from Kickstarters are always helpful, and improved all of my projects. All of them eventually made it (or are making it) onto the online market.

Moedls took about a year to develop, on and off, and during that time I was constantly looking for better lasers and rotating platform, and I think about halfway through, I knew I’d be eventually putting it on kickstarter, because I couldn’t find decent hardware. I knew the funding goal would be much higher too, since all of my other projects have been built by myself (other then the magnets, which what the funding goals for those were based on). With the Moedls hardware, there are at least 4 sets of molds to be made, totally almost $20k. After I got pricing back for the molds, prototypes, and Minimum Order Quantities, I came up with a figure that was based on ‘worst case’ backer configuration. (Believe it or not, worst case is everyone buying the Pro version. Those powell lenses are quite expensive. I wanted to make sure the backers had the option of getting the absolute best possible scan though, so its worth it.)

3DEngr: Do you have other projects in mind after moedls? What’s next?

Wow… Right now I’ve got my head very much wrapped around Moedls… The hardware is pretty much finalized (pending any little tweaks once I get the final prototype) although a stretch goal might be to add an Arduino board with usb/bluetooth to control via your mobile device and/or laptop. I’m really concentrating more on getting the final holes closed so it can be sent straight to a 3d printer.

3DEngr: Best of luck to you John. As a backer I am excited for all the kinks to be worked out so I can play with my new Moedls scanner.

Update:: John’s latest Kickstarter update says the hole filling portion of the software is complete, now on to the challenges that originally got the project started – a smooth rotating platform.

Update:: John’s latest Kickstarter update says the hole filling portion of the software is complete, now on to the challenges that originally got the project started – a smooth rotating platform.