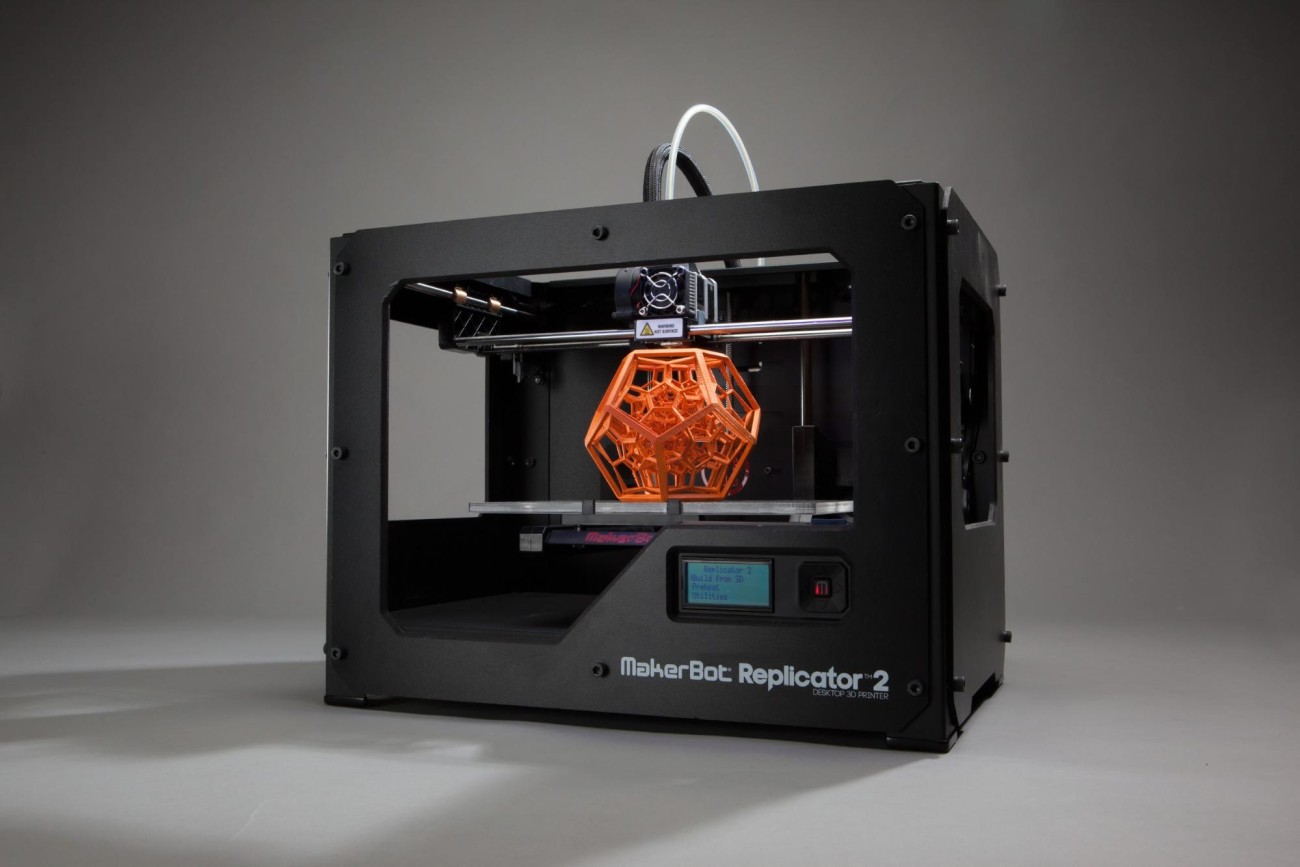

Do you own or are you considering buying a Makerbot or another similar desktop 3D printer? That’s great—there are a ton of quality options at relatively low-cost entry points to help you get started with 3D printing for rapid prototyping.

But while desktop 3D printers are great for certain things, they also pose some limitations around resolution, capacity, build bed size, and material variety.

So what are your options for higher quality 3D printing? Well, there are two:

- Buy a better (i.e. more expensive) 3D printer

- Outsource high resolution 3D printing

To help you make the leap from rough prototypes on a desktop 3D printer to high quality visual models and functional prototypes, I’m going to outline the pros and cons of owning a desktop 3D printer and then outline your options for getting high resolution 3D printed parts.

Desktop 3D Printers: Pros and Cons

In the early days of prototyping a product idea, the key is to test early and often. This means you should get out of the digital space as quickly as possible to create rough physical prototypes for more tangible feedback.

So when you’re iterating on a design early-on, you don’t need to use expensive high-resolution materials for prototyping and a desktop printer like a Makerbot, using dirt-cheap PLA, is a great tool.

But once you’ve nailed down the basic form factor of your idea and you want to start prototyping mechanical components like light pipes or snap fits, or you want to create a polished-looking visual model to show prospective investors, the resolution capabilities of your desktop 3D printer become very limiting.

So what’s the next step?

Option #1: Buy a Better 3D Printer

Your first option is to just buy a better (i.e. more expensive) 3D printer. Here’s a quick breakdown of the three tiers of 3D printers by pricetag:

- Tier 1: <$10k (desktop 3D printers)

- Tier 2: $10k – $50k

- Tier 3: $50k+

In the sub-$10k tier, you have your Makerbots, Printrbots, and Form 1 3D printers. These are usually used by solo entrepreneurs, and have smaller print beds and lower resolution.

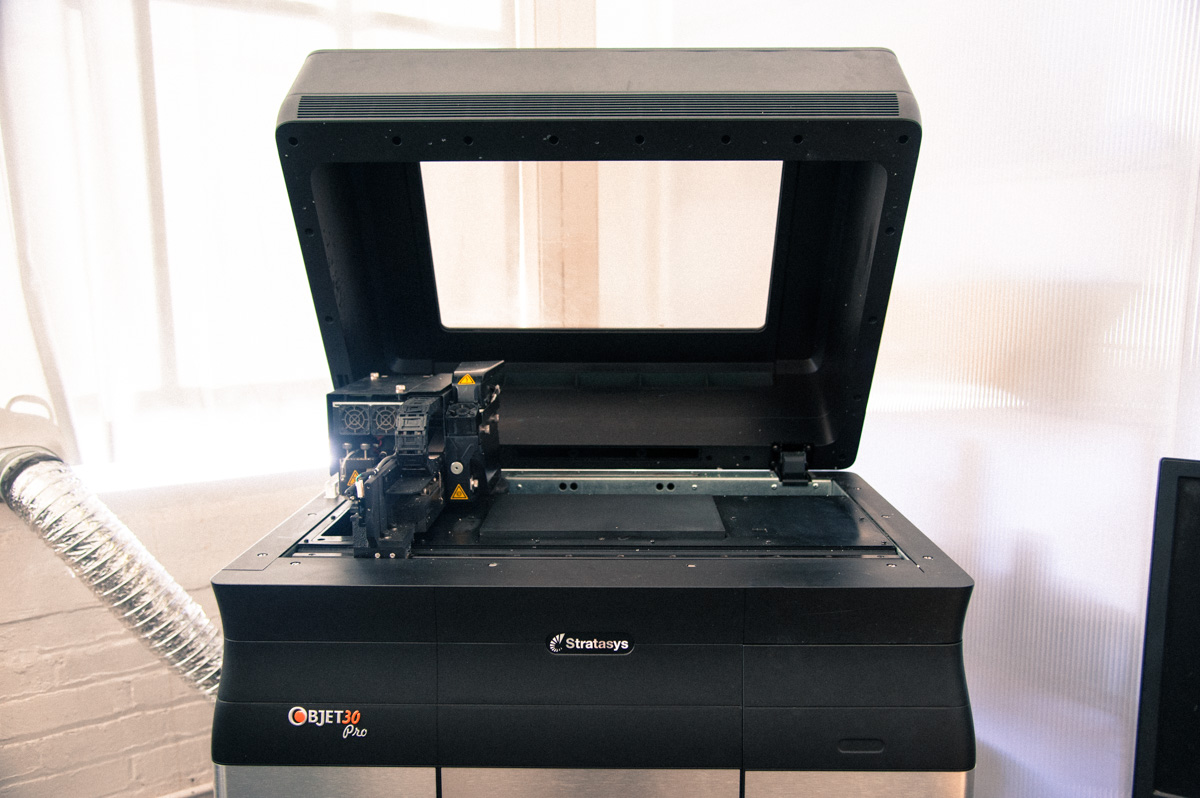

Tier 2 printers include Uprints, Objet 30, and entry ProJet machines. These are geared towards professionals, industrial design firms, and universities, and have higher resolution and reliability.

The final $50k+ tier are powerhouse machines that include Projet, Eden, Connex, and Fortus. They have the largest print beds and finest resolution, and are often used by Fortune 500 companies with deep pockets.

As you can see, price is a very limiting factor when looking for higher quality 3D prints. And even if you can afford the upfront costs of one of these machines, you still need to consider the costs of your time to maintain these workhorse printers, including time spent:

- cleaning the machine

- ordering spare parts

- troubleshooting and working with the manufacturer’s technicians on repairs

- selecting, purchasing, and loading materials

- safe disposal of material waste

- managing facility requirements

Trust me—I’ve been there and it’s a lot to manage.

Option #2: Outsource High Resolution 3D Printing

So if you can’t afford a Tier 2 or Tier 3 printer, or don’t want to deal with the burdens of maintenance, what are your options for higher resolution 3D prototypes? That’s where outsourcing comes in.

Once you’ve nailed down the form factor or your product, printing multiple prototypes with your desktop 3D printer, you can use an online service like Fictiv to order 3D printed parts, choosing from a wide range of materials, machines, and technologies. Here’s a quick summary of the advantages of using an online 3D printing service:

- Material Selection: Variety of options like transparent material, flexible material, and multi-material stiff and flexible parts.

- Technological Capabilities: Get high resolution with PolyJet and SLA technologies, or complex internal geometries only printable using wax support.

- Capacity: No need to worry about printing backflow or printer failures.

- Costs: Get the benefits of using multi-hundred thousand dollar machines while paying for just the material cost, support, and run-time.

- Time: It’s not easy to manage and maintain a 3D printer in top shape and it is very time consuming. The less time you spend maintaining and operating machines, the more time you have to focus on building a successful, innovative product.

So if you find it valuable to own a desktop 3D printer for building low-resolution prototypes, that’s great. Now you also have a path to ordering high resolution 3D printed parts to supplement your prototyping workflow for faster hardware development.

About the Author:

Dave Evans is the Co-founder of Fictiv, a hardware development platform for engineers and designers that offers an online tool for ordering 3D printed parts in 24 hours.