This guest 3D printing education article is authored by Quilen Blackwell, President and Founder of the Chicago Eco House.

The Chicago Eco House, an inner city nonprofit with the mission of alleviating poverty through sustainability on Chicago’s south and west sides, was invited to the first educator 3D printing training at the University of Louisville. Educators from community colleges and high schools from around the country came to get hands on training from 3D printing professionals as well as to get an idea of how to steer our youth in the industry to take advantage of emerging industry trends.

The primary training instructor, Carl Tackett, has over 20 years of 3D printing experience as he worked on films such as Transformers and Star Wars, and currently 3D prints parts for aircraft. He emphasized to the attendees that we are in the midst of a 4th industrial revolution where cyber physical systems merged with 3D printing is enabling faster, cheaper, and better production that can create geometric products that previously wasn’t possible. Furthermore, 3D printing allows for anyone to become a manufacturer of personalized and customized products that could lead to a rebirth of the cottage industry.

This is how we use 3D printing with our youth at the Chicago Eco House. Our youth live in high poverty, high crime areas with very limited economic opportunities. Therefore, we decided to use 3D printing as a way to teach youth valuable STEM skills while learning how to build a 3D printing business that sells jewelry and fidget spinners that can generate some income for them and their families. We work with youth ages 8 to 13 in a micro business where they design 3D models, use the slicing software to manage the prints, maintain the machines which includes unclogging the nozzle when necessary, perform post production on their products, and handle the sales and marketing of the business.

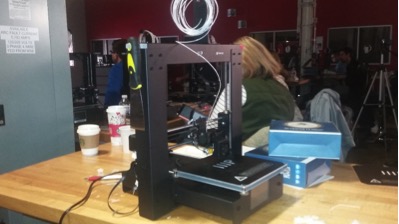

In terms of the hands on training element of the conference, attendees were given a 3D printing kit that included a Monoprice 3D printer, two spools of PLA filament, two extra .4mm nozzles, nozzle cleaning filament, PTFE tubing, 3D printer toolkit, two memory cards, 1 memory card reader, and CURA 3D printer software. The instructional team at the conference spent several hours showing us how to optimize the performance of the Monoprice 3D printer with the additional tools included in the kit. Some of the tips that mentioned to get the most out of the printer included keeping the filament dry at all times by storing it in a zip lock bag with gel packet dehumidifiers, leveling the bed by moving the extruder over all four corners of the build plate when the printer is turned off, and modifying the print settings in the slicer application to improve print quality.

The session ended with a presentation by Eric Wooldridge of Somerset Community College on the specific industry trends that 3D printing will open up over the next several years. 3D printing is enabling parts to be manufactured using less material while also being more durable. For example, a LEAP fuel nozzle that is 3D printed uses 25 percent less material and is five times more durable than the same part that is produced using conventional techniques. These kid of weight reductions and durability gains can be found for thousands of other parts across several industries. As a matter of fact, General Electric believes that 3D printing represents a 12 trillion dollar opportunity. This means that youth who are trained in 3D printing today can expect to get jobs as 3D printing technicians, secure lucrative production contracts, be a part of building new manufacturing plant locations, and start innovative businesses over the next 10-15 years. Just about any part today can be 3D printed in the near future, which will represent a massive wealth opportunity for those who are well positioned.

3D printing will play a big role in the near future in reshaping the way stuff is made. We are on the ground floor of a new manufacturing revolution that will create new opportunities for potentially millions of people around the world. However, it is how we train our youth today that will determine if they will be a direct beneficiary of this emerging technological gold rush.