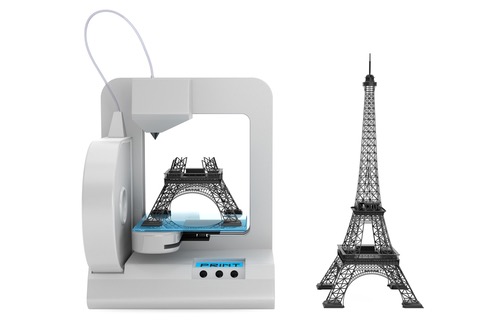

Just in the past five years, 3D printing has boomed. Starting out, users could create only small items such as knickknacks, but his is no longer the case.

3D printers now have amazing capabilities. These small but powerful tools can create objects ranging from clothing, to toys, jewelry, artificial limbs, and cars. Because you can use 3D printers to create virtually anything you can imagine, they have the power to innovate many industries.

3D printing is already affecting the areas of construction, design, and leasing. With the right materials and the knowledge to build a structurally sound dwelling, architects have already used these printers to create 3D apartments and houses.

This ability will soon change how people buy houses. They can have them built for a lower cost, which could change the housing industry worldwide. The residential and commercial real estate industries will continue to be influenced by this innovative technology in the years to come.

How It’s Accomplished

This type of construction is done using large printers that use a special concrete mixture. This mixture is very thick so that it supports itself as it sets. The entire house cannot be created in one sitting. Instead, parts of the house are created and then put together. Plus, each object is created layer by layer from the bottom up – just like an inkjet printer can print the same object hundreds of times on the same piece of paper.

3D printers can create curved objects that are hollow inside to save on material. There are also plans to make the house building process more automated to save time and money.

Advantages and Disadvantages of 3D Printing

3D printers offer many advantages over current construction methods. The construction process is faster and more accurate. Printing is done off of a 3D model, so unless there are issues with the model, errors are very unlikely.

3D printing also reduces construction costs by as much as 80%. Humans are no longer needed to erect the building, so this could potentially save hundreds of thousands of dollars in labor costs per home.

There is also a huge reduction in waste. 3D printing is environmentally friendly. It uses 100% recyclable materials, so any components not used can be broken down and used in another project.

There are also no safety issues to complicate the process. Because no heavy equipment or power tools are needed, the construction process is very safe.

While 3D printing offers many benefits, there are some major disadvantages. Using 3D printing instead of traditional building materials can seriously disrupt the construction industry.

Because no workers are needed to build, 3D printing will reduce the labor force, which could lead to huge spikes in unemployment. Tools and equipment will no longer be needed, so industry manufacturers might see a decreased interest in their commodities.

There are also some limitations to 3D printing. One printer may not be able to print everything you need, so you’ll be limited by which materials you can use.

In addition, because these printers are large, there may be issues regarding transporting these printers to various locations, as well as storing them. Plus, using digital models comes with risks. Any errors in the file can cause major defects that can ruin the building.

Current Technology

Most commonly, 3D printing is used by commercial real estate professionals to create 3D models to help clients visualize designs. In the past, these models were drawn by hand and took many hours. Today, 3D printers can make these models effortlessly, with very little time requirement.

Some companies are taking this a step further and using 3D printers to create life-size houses and buildings. WinSun created the first 3D printed apartment building in 2015. At five stories tall, it is considered to be the largest building created by a 3D printer. The company also created an 11,840 square foot villa for just $161,000.

Another achievement for the company was creating 10 houses in just one day. These single-story dwellings are made of a cement mixture and look no different than ordinary houses. The cost clocks in at just $5,000 per house.

What the Future Holds

The next decade holds many exciting changes for the commercial real estate industry. The demand for warehouses will decrease because 3D printers can customize materials for each project and create them as needed. There will be a reduced need to keep materials on the site and store them, which will influence distribution needs.

While some people might lose jobs thanks to the streamlined processes of 3D printers, this technology could bring manufacturing jobs to the United States. 3D printing will make it more cost-efficient to print materials this way instead of getting materials shipped here from other countries. These will be high-skilled jobs.

It’s expected that, in the future, houses will no longer have to be created in pieces. Super-sized printers will be able to create houses in one sitting. They will be fully constructed and available for quick occupancy.

Some companies are experimenting with different materials. They are using plant oil combined with other ingredients to create buildings that are environmentally friendly.

With houses able to be built at such low costs, the housing industry is expected to boom. More families will be able to afford low-cost housing, making the American Dream a reality for thousands of people. Once the technology improves, users will likely be able to use 3D printers to design and build their own homes in the future.

About the Author:

For more than 20 years, Robert Barrett has been recognized as a leader in the real estate industry. Under the tutelage of his father, Roy Barrett, he learned to specialize in finding undervalued assets, and his negotiating skills have led to many successful real estate acquisitions and developments. Barrett Properties currently owns over 100 properties including shopping centers, warehouses, apartments, condominiums, and storage facilities.

For more than 20 years, Robert Barrett has been recognized as a leader in the real estate industry. Under the tutelage of his father, Roy Barrett, he learned to specialize in finding undervalued assets, and his negotiating skills have led to many successful real estate acquisitions and developments. Barrett Properties currently owns over 100 properties including shopping centers, warehouses, apartments, condominiums, and storage facilities.