A sketched bend is one of the easiest ways to change an existing sheet metal part. In a similar fashion to the “Jog” command a sketched bend can create a feature without adding any material. This helps to maintain a conceivable flat pattern without having to create too many relation rules. A one line sketch will take care of defining the feature but positioning it is key for component fits. Thankfully the bend positions are laid out in an easy to understand diagram.

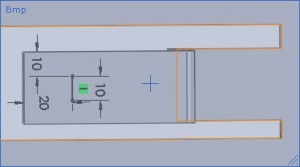

So then it comes to defining this one line sketch. Recently I read a post by Matt Lombard where he busted the “Fully defined sketches are faster to rebuild” myth but I thought this would be a good tool to get some more evidence. For a Sketched bend even a simple 1mm long line will cause the same feature as a fully defined and extended line. Both of them simply tell the program where to make a bend. So what difference does it make to fully define where the bend goes. Here is a simple line section used to create a bend.

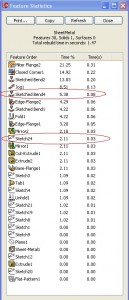

Total rebuild time was .06 seconds undefined. And now below is the fully defined version. You can see the rebuild time for the sketch has increased significantly (0.00sec >>0.03sec) and the feature (0.06sec>>0.08sec) for a total rebuild of 0.11sec fully defined.

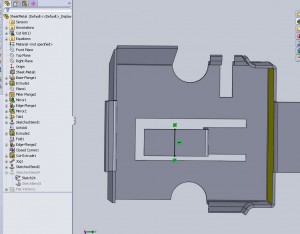

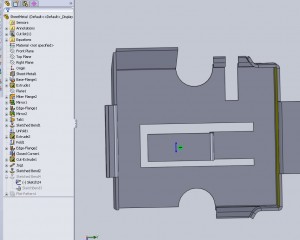

So what is the result of this result of all this to the model? Nothing aesthetically, all three produce the part shown below.