The jog feature in sheet metal is yet another tool that simplifies design features. Many times a 2 bend step is required for mounting, to avoid other features, or create a simple wall and using the jog feature combines them into one item.

A few of the benefits of jog.

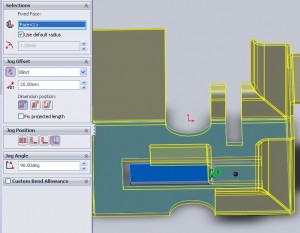

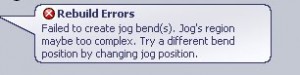

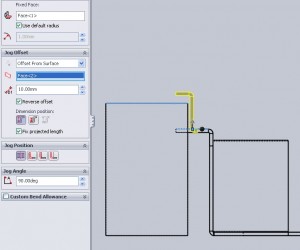

In the feature manager there is a selection box for “Fix Projected Length”. By Clearing this length the software will ONLY use the material that is already existant. Now if the dimensions of the jog require additional material to be added an error occurs.

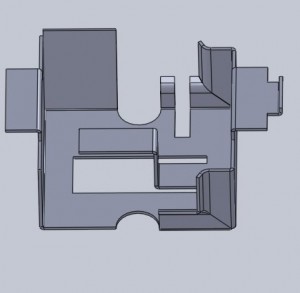

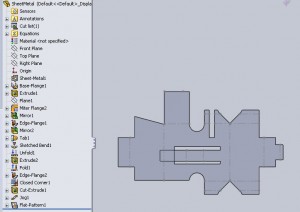

This is a huge help considering that all sheet metal parts must be flattened. If there is a limited amount of material available the jog feature (with Fix Project Length cleared) will lock in this design intent. Skip this step and solidworks will still let you design a part, and even flatten a part which can not be created. Take a look at the images below, see something wrong? You should. This part can not be created from a single flat sheet of material, look at how the flat patten overlaps itself.

So when do you use a fixed projected length? Use it when you can add material, on the outside of parts. This is great for in context modeling of multi body parts or assemblies.

Above I’ve taken a tab that would have caused interference and moved it while still keeping it’s length in one direction. The alternative to using the jog feature here would be to Cut>Edge Flange/Tab>Edge Flange Tab or Cut>Miter Flange the part. Even though the jog feature is system intensive on the rebuild the relations required to capture the design intent are much easier to input using a jog and it keeps the total feature count down.