Not to be outdone by printers that use chocolate or paper, ExOne’s M-Lab printer outputs materials in metal. Direct Metal Laser Sintering or DMLS works with under nearly the same principles as many of the printers that use plastic but instead can use proprietary materials to produce parts in stainless steel, bronze, tungsten or glass. Creative applications by researchers and academics (the key market identified in ExOne’s sales materials) will only serve to expand the capabilities of these machines. Consumers and evangelists who are waiting for in home use may have a few years to wait but the ability to layer such a variety of materials, each with unique and desirable physical properties, will be what leads to the true revolution. Even today these machines are capable of shortening the lead time for highly complex parts whose only alternative is costly and time consuming machining.

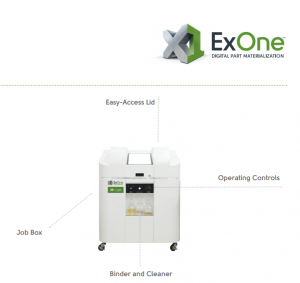

The ExOne line is setup to bring additive manufacturing to a variety of processes. There digital part materialization includes not only metal, but glass and sand as well. None of their machines are yet positioned for the consumer market. They do however offer such a variety of outputs that it is possible to utilize them in place of machine shops, casting factories, and complicated multi-step manufacturing. If there is a 3D printing industrial revolutioncoming (as opposed to a consumer revolution) expect ExOne machines to play a part in it.

ExOne also has a cool interactive walk through on the process of additive manufacturing on an industrial scale.

Previous in the series “10 Unique 3D Printers”: Fortus by Stratasys

Next in the series “10 Unique 3D Printers”: ZPrinter by ZCorp/3D Systems

Read more about 3D Printing on 3DEngr