To learn more about DFAM from SolidProfessor, Forecast 3D, SOLIDWORKS, and HP. Register for their webinar: Demystifying Additive Manufacturing.

Many years ago, injection molding and subtractive manufacturing were brand new, groundbreaking technologies. Injection molding, the act of creating parts by injecting heated material into a mold, and subtractive manufacturing, the act of producing parts by eliminating material from a block, are no longer groundbreaking technologies, but are widely used and have been adopted as common practice. At the time, these technologies brought about a faster and more precise way of creating parts in mass and allowed the machining industry to innovate and grow at a rapid pace.

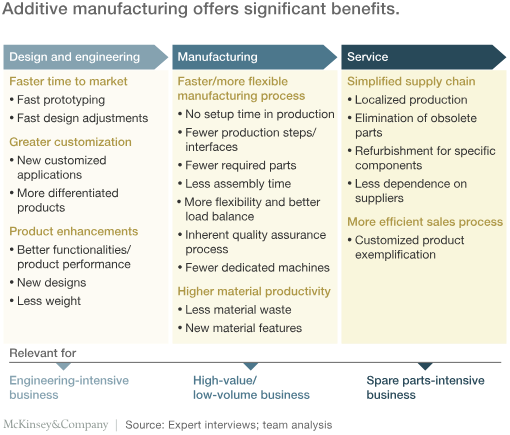

We’ve reached another point in engineering and machining history where new technology is quickly advancing and these methods are being replaced with the new and improved additive manufacturing process, the act of controlled material addition in order to produce parts in mass. Additive manufacturing allows for mass customization, reduced material waste, lower costs, and increased efficiency compared to injection molding, extrusion, or subtractive manufacturing processes. Companies like GE and Boeing are swiftly and immediately replacing older technologies, processes, and assembly lines with additive manufacturing due to the immense benefits it brings.

Here are three reasons to start using this new technology, even if you don’t have a massive budget to work with.

1. Inexpensive prototyping

Early stages of development are faster and less expensive with additive manufacturing. A single design can be iterated on so quickly that it makes the development of new products cheaper and easier to create because it no longer requires outside machining or fabrication. This evens the playing field for small businesses competing with larger corporations.

2. Reduced storage costs

With additive manufacturing, you can reduce inventory, therefore reducing costs to store products or parts. Using additive manufacturing processes, there aren’t cost savings associated to printing parts in mass, so small businesses or businesses working with smaller budgets can reinvest the money once needed to store inventory into other areas of the business. Quick production means you can have the parts you need on-demand.

3. Minimized waste

Additive manufacturing greatly reduces waste and thus costs because only the material that is needed is actually used in production. Not only does this leave a smaller environmental footprint, but it also frees up capital for other areas because material costs are very predictable.

To learn more about DFAM from SolidProfessor, Forecast 3D, SOLIDWORKS, and HP register for their webinar: Demystifying Additive Manufacturing.

About SolidProfessor – SolidProfessor provides next generation learning for teams, schools, and individuals to keep up with rapidly evolving engineering tools and technologies. Their online learning resources include video tutorials, hands-on exercises, and skills assessments. Sign up today.