3D printing involves creating a three-dimensional object from a digital model that has been built on a computer. Design instructions are sent in a file from the computer to the 3D printer, where it selects the correct materials and “prints” them together layer by layer to form the object.

What Is 3D Printing?

3D printing is the process of making a three-dimensional solid object from a digital model on a computer. While there are several different types of 3D printing, all 3D objects are generally built out of layers.

Unlike previous subtractive methods such as machining, turning, milling and sawing, 3D printing technology uses an additive production technique. This means that materials are quickly added in layers, where as subtractive methods cut away and mold objects from a block of material.

3D printing technology has already been used for jewelry, footwear, industrial design, architecture, engineering, aerospace, medicine and education.

History of Stereolithography

The first commercial 3D printer was based on a technique called Stereolithography, which was invented by Charles Hull in 1984. These Stereolithographic 3D printers use a UV laser beam that traces and slices objects during printing. Stereolithographic printers are still considered one of the most accurate types of 3D printing.

How Does 3D Printing Work?

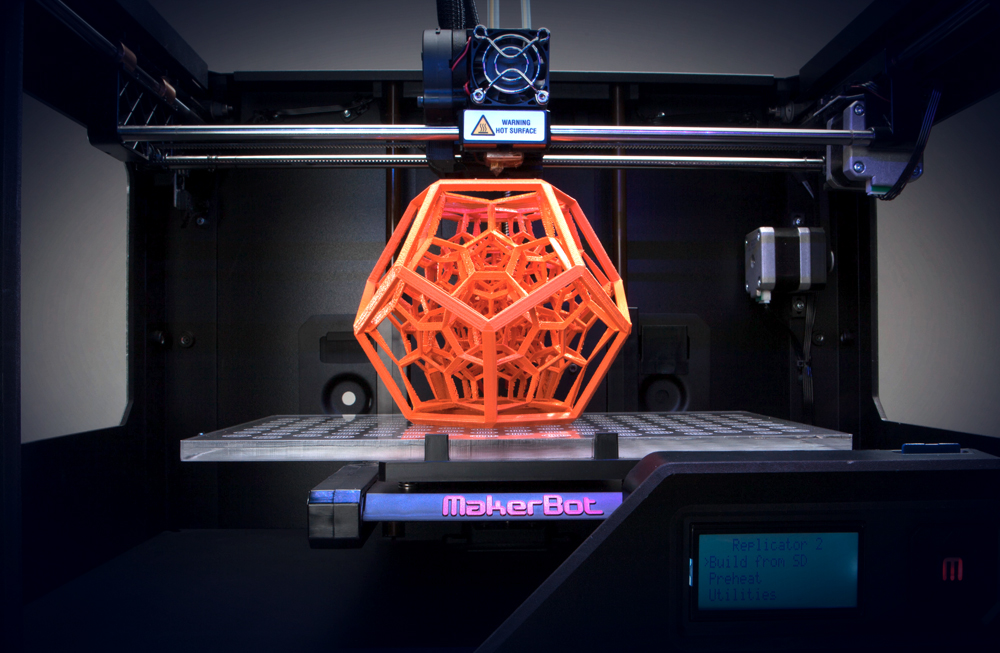

Here is how 3D printing technology works. First, a three-dimensional object is modeled by a designer using computer software. This is then put into a file which is sent to a 3D printer, where the correct printing material is selected. The printer then releases small amounts of the material in a layer–by–layer process, eventually producing a 3-dimensional object. You can watch videos of 3D printers in action.

One important distinction when discussing 3D printers is whether or not it is an Industrial or Commercial model. 3D printers have actually been used in industrial settings for the last 30 years, while consumer and small business-oriented 3D printers are just taking off.

Industrial 3D Printers

Industrial 3D printers are usually much bigger and more expensive than the commercial ones, and pack a lot more horsepower and speed. The automotive industry is one example of an area where 3D printing technology has had its root for some time. Most of these applications are currently for prototyping and not the actual assembly of cars that will be on the road, although this trend is changing as 3D printing technology becomes more powerful. Companies like BMW can use 3D printers to quickly and efficiently build prototypes of production parts.

Prior to 3D printing technology, the building of prototypes took more time and dedication of resources, and was more expensive to get the proper equipment and expertise. With the current state of the technology, companies can quickly print prototypes from state of the art 3D printers quicker than ever before. These processes can even take as little as a few minutes, with engineers adding recommendations and changes that can be brought to life in the physical world through this technology. 3D printers have already had a noticeable impact on the industrial sector, but there is another area that has been experiencing benefits for some time now.

The medical field has seen many useful applications of 3D printing technology, whether it be printing organs and prototypes that are custom fitted to individuals, or printing arteries that could eventually be used in treating heart problems. Some of the hottest investment action in 3D printing technology is currently happening with biomedical 3D printer companies that will help the medical field for years to come. Industrial 3D printers can range anywhere from $9,000 to $600,000.

Commercial and Home 3D Printers

Commercial and home 3D printers have yet to really take off, although in the last year we have seen a push by companies to popularize them. These companies are researching and investing in ways to get 3D printers into homes and believe that there is promise for home 3D printers the future.

One obstacle getting in the way of 3D printing becoming mainstream is cost. Producing 3D printers at a consumer level is still expensive due to the difficulty in getting 3D printing technology down to a desk printer size. Large industrial printers are very expensive and are still in high demand by many industrial companies, and are often set to only build certain types of pre-set parts. This is much less expensive than designing smaller printers that are more advanced in their customization options.

Despite this, there are many efforts to bring 3D printing to consumers. 3D software is being developed and shared as open source amongst the public, which will likely bring advances in the technology and greater ease of use. There is also a 20 year old patent from mega-companies Stratasys and 3D Systems that is coming to an end, which will cause new companies to enter the market and lead to competition which will ultimately reduce prices. All of these factors would lead to the introduction of 3D printers at a consumer level.

Commercial 3D printers could be used for many practical things, like home renovation, cooking, small business, gardening and home engineering. Although Consumer 3D printers are not well established, they usually go for around $600-$3,000 dollars.

The Future

Theoretically, in the future anything will be able to be printed from a 3D printer. One will be able to print parts or tools for a project being worked on, clothing, a chocolate bar, or even a house. The possibilities are endless.